Everything You Can Make With A Laser Engraving Machine: Hands-On with the xTool F1 Ultra

Everything You Can Make With A Laser Engraving Machine: Hands-On with the xTool F1 UltraNot everyone has the budget for high-end gear. I know I’d love to own a 3D printer, but I genuinely don’t think it’s the kind...

Not everyone has the budget for high-end gear. I know I’d love to own a 3D printer, but I genuinely don’t think it’s the kind of device you buy first and adapt to later. Laser engravers too – I’d probably love to have one, but it’s a want rather than a need. The missing piece of the puzzle, however, is potential. Any good marketer will tell you that potential is what drives consumer adoption – yes I sound salesy, but I’m getting to the point in a bit. I never knew I needed a laser engraver – until I saw exactly the kind of stuff I could do with it.

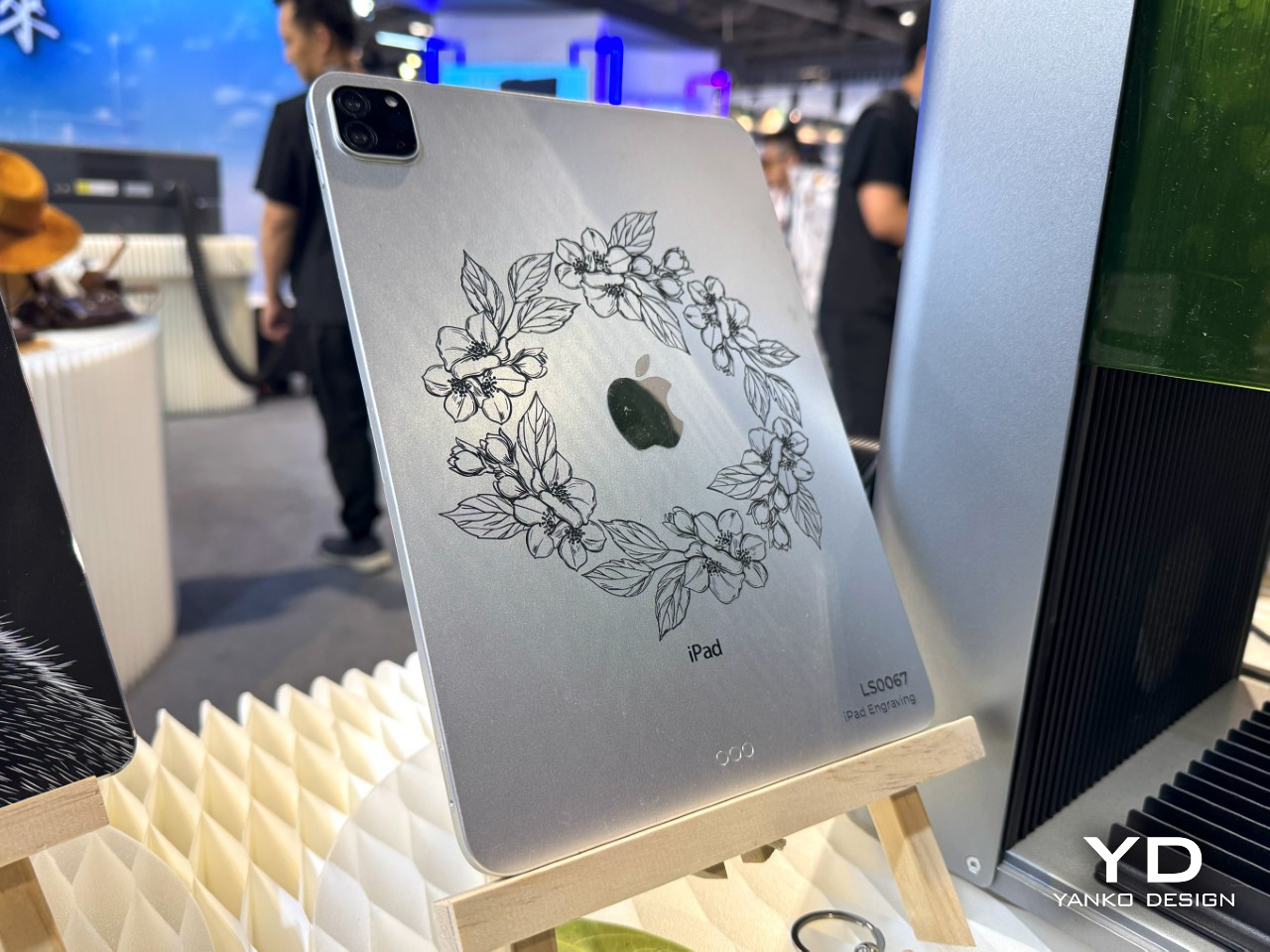

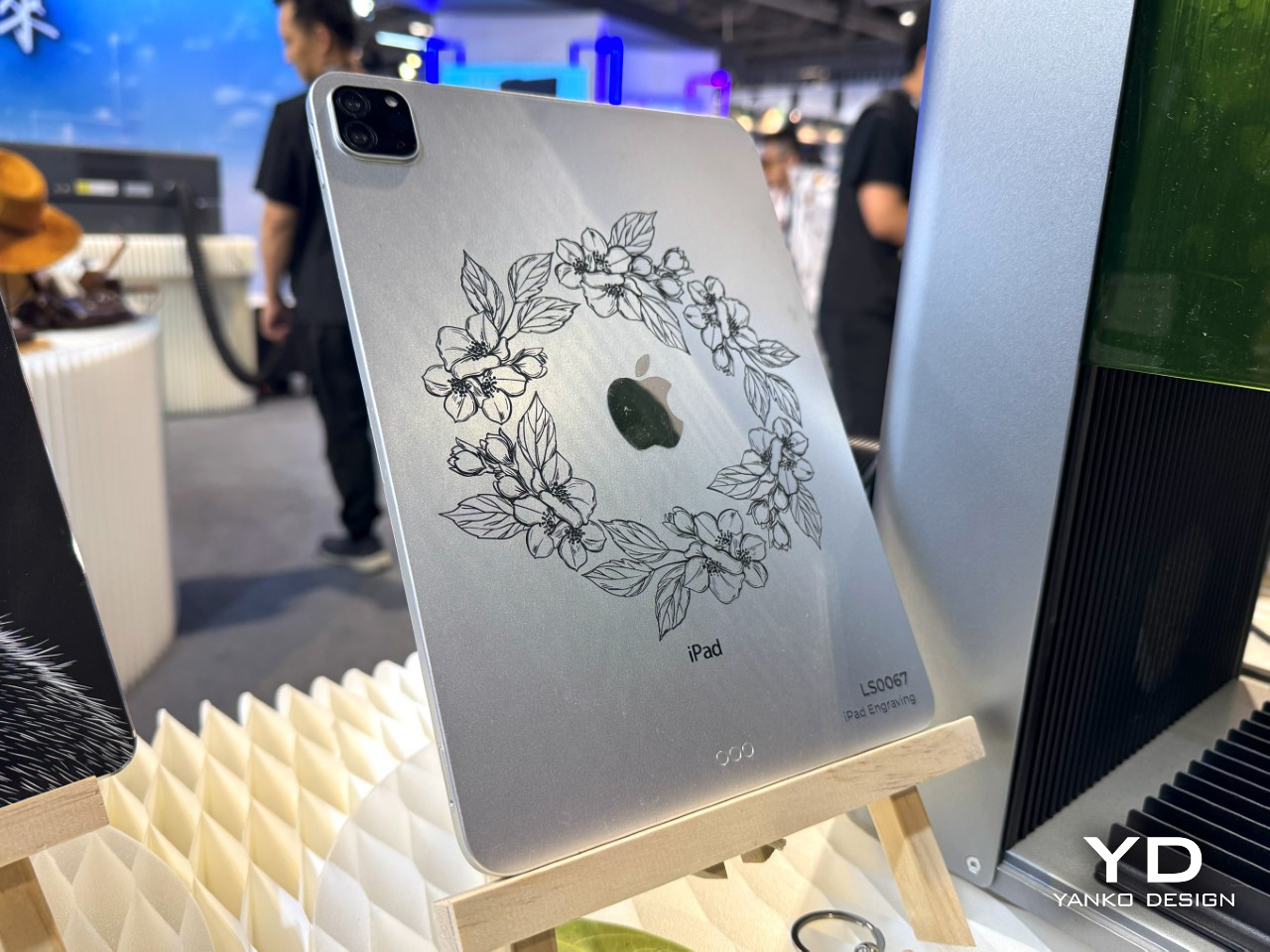

Two weeks back, I was in Macao for the BEYOND Expo – an exhibition targeted at highlighting tech innovation east of the Pacific. With literally hundreds of exhibitors, it was the perfect ground to meet companies, see products, and understand their potential. It’s also where I saw the xTool F1 Ultra, and it wasn’t the machine that excited me as much as it was the stuff around it. Strategically placed all around this dual-laser engraver were an entire bunch of products made BY the F1 Ultra. From cutting to etching, this machine could work on plastic, metal, wood, fabric, leather, heck, even leaves (I got a cinnamon leaf with my face etched onto it)… and that’s when it hit me. A laser engraving machine has TONNES of potential – not just for craftspeople and tiny studios. But for hobbyists, designers, and anyone who loves spending time in a workshop.

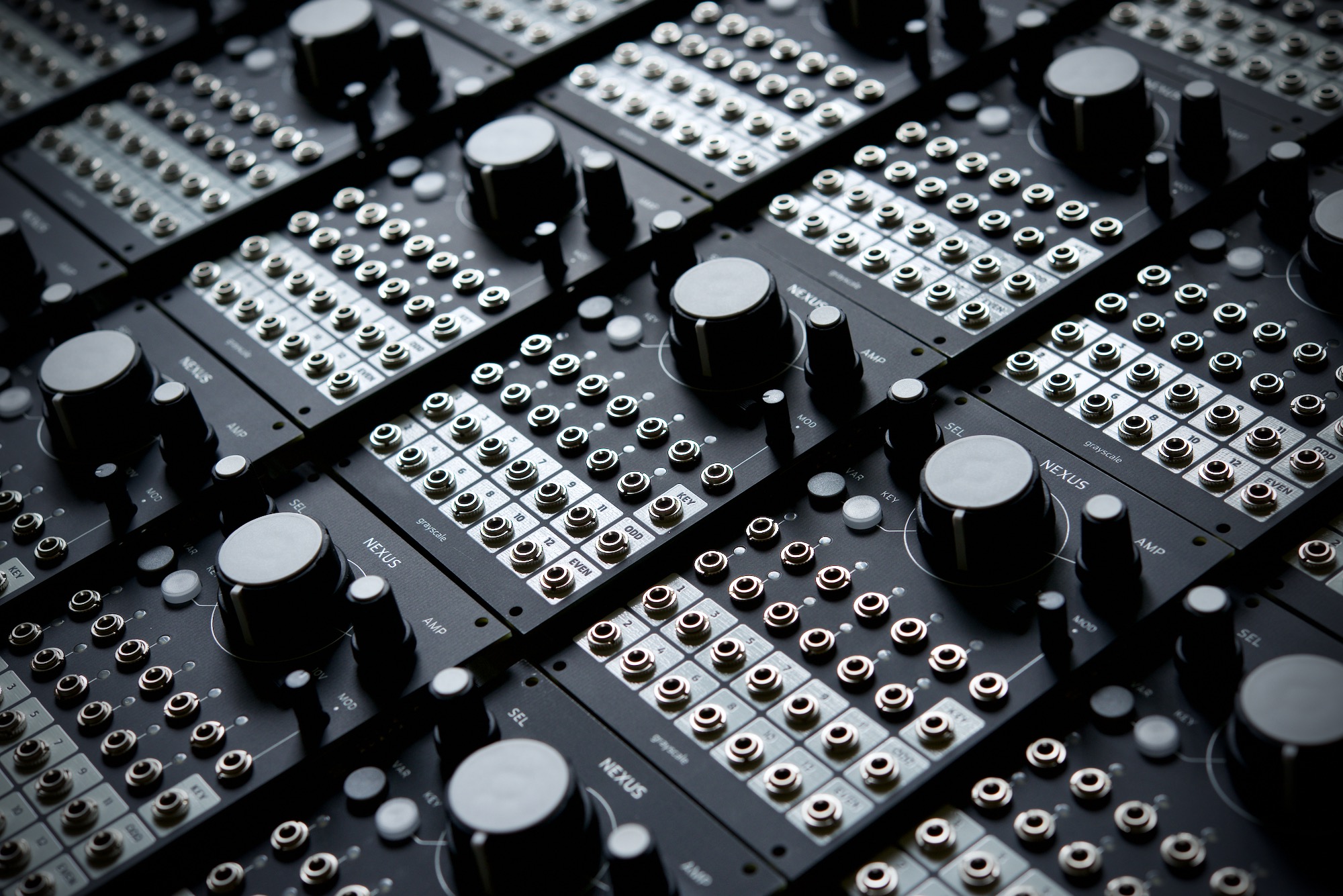

This article isn’t about the F1 Ultra, but rather about all that it can do. Just for posterity, the xTool F1 Ultra is the world’s first dual-laser engraver that combines a 20W fiber laser and a 20W diode laser. The fiber laser (1064nm, if you’re into the nerdy details) is your go-to for metals, capable of slicing through thin brass, stainless steel, and aluminum with surprising ease (we’re talking 0.4mm, 0.3mm, and 0.2mm, respectively ). The blue diode laser (445nm) handles the softer stuff – wood up to 15mm and acrylic up to 12mm. The F1 Ultra’s impressive 10,000 mm/s speed, combined with features like the smart camera and autofocus, means you’re spending less time tweaking settings and more time bringing your ideas to life. Sure, at $3,999 it’s not exactly impulse-buy territory, but that price tag feels more and more justified once you look at what this beast can do.

Everything you see here was created by either the F1 Ultra, or its larger sibling, the S1, which uses the same laser cutting/engraving technology, but offers a larger, rolling bed so you could potentially feed endless rolls of material in and have the thing continuously etch/cut a design. Both machines, however, work with the same broad spectrum of products, and if you’re looking for the most obvious application, it’s definitely leather.

The three pictures here (starting with the Burberry-branded wallet) are all examples of what laser etching on leather can look like. It’s important to note the versatility of these different products, because you’ve got A. Tanned leather on top, B. Suede in the middle, and C. Dyed leather below. All three can handle the controlled blasts of a laser remarkably well. Suede doesn’t develop as much of a darker color as tanned leather or dyed leather, but that’s probably because of the tanning dye or inks burning too. Either which way, the laser machine works well with all kinds of surfaces, even curved ones like the shoe below, allowing you to customize your belongings/products with a variety of prints and styles.

The laser engraving works on fabrics too, creating a washed/bleached look rather than a burnt look. This is probably because the laser has an effect on the dye as well as on the cloth itself, revealing the lighter fibers of the fabric underneath. This saves you the effort of taking sandpaper to your denims or meticulously painting them with bleach. Laser offers incredibly precise detail, letting you create intricate prints that just look fantastic on thick fabrics like denim. You can work with other fabrics too (preferably thicker ones), and yes, you can crank up the power to cut fabrics too, using it as an alternative to a scalpel. Fabrics, paper, leather, plastic, even thin sheets of metal.

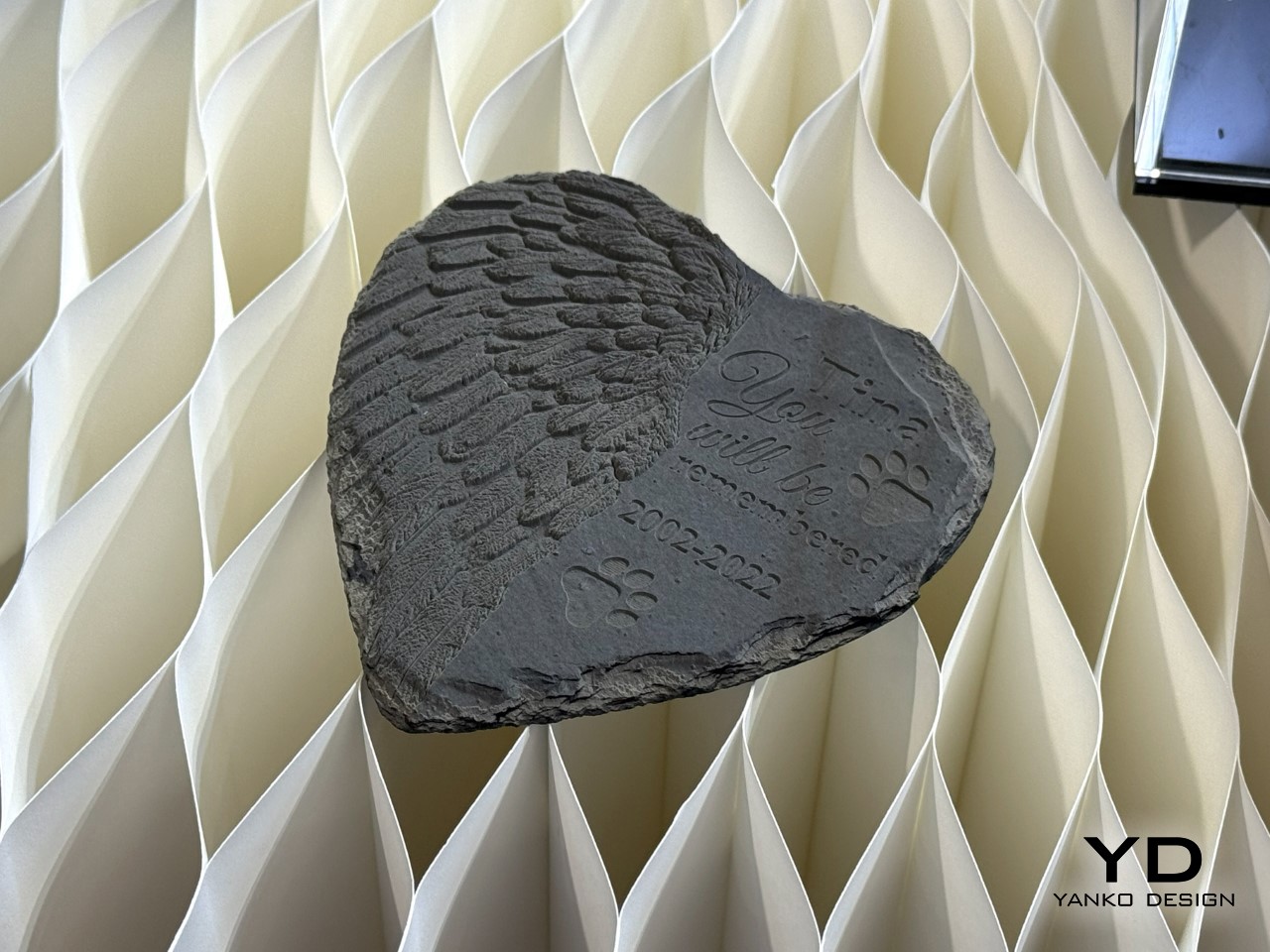

Remarkably so, the machine can work on stone too, especially less dense stone materials like slate. Here we can see the effects of surface-level as well as deeper engraving jobs. Above, a menu is etched onto a slab of slate, creating a design that looks hand-made but is entirely machined. It’s rustic, gorgeous, and can’t be wiped the way chalk can. However, if you want to work with depth, the laser can cut into material too, rather than just marking the surface.

Above and below are both examples of lasers’ effect on slate and wood, respectively. The output of your engraver plays a crucial role in determining the power of the machine. A higher laser output (maybe 40W or 20W) can literally perform a controlled erosion of material, carving it instead of simply etching it. The slate one is impressive, but the wooden cat below truly blew my mind, with a kind of relief that you’d expect from a CNC machine, not a laser one.

But laser machines can cut too, as I explained earlier – and the best example of it is above and below. While laser machines are mostly preferred by people who work with 2D designs, they’re great for 3D too. The image above is of a doll made entirely through laser cutting. You cut the various parts out, assemble them together, and you literally have a 3-dimensional toy.

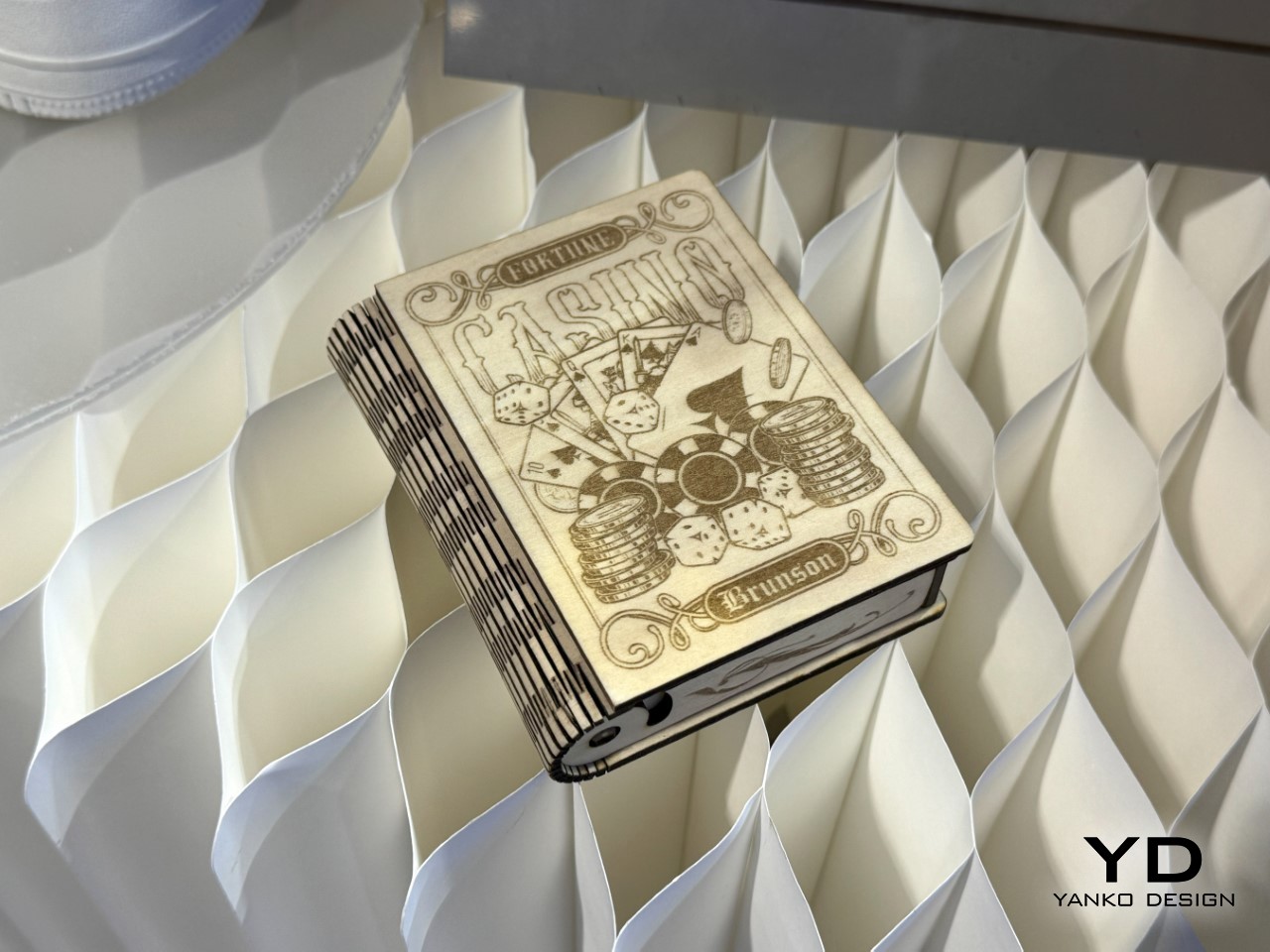

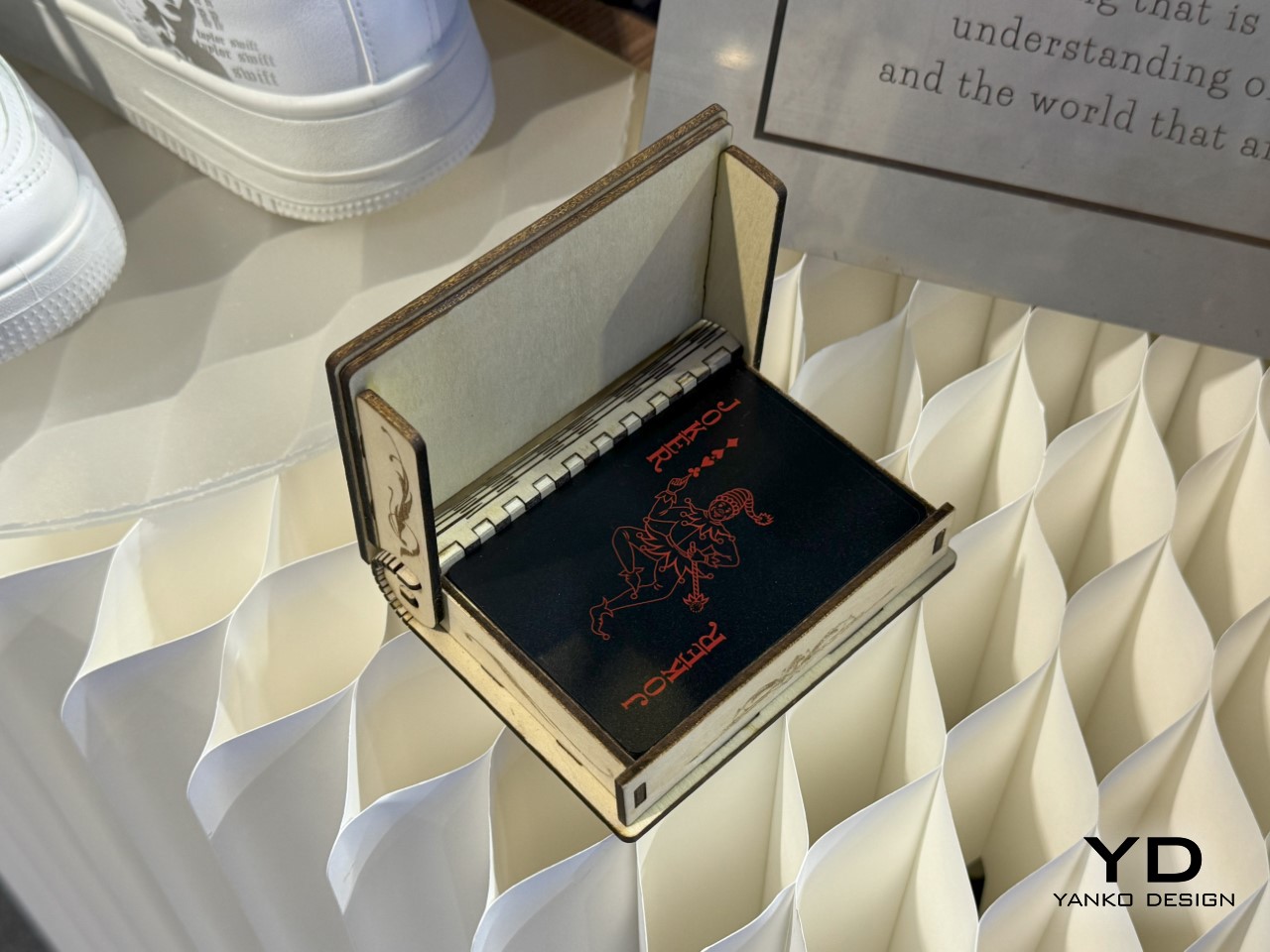

Want to look beyond mere cut-and-assembly-style designs? You can literally make wood sheets bend too, simply by cutting a controlled dash pattern on them like the one shown here. This turns wood from a stiff plank to something you can wrap around 2D curved parts. This ability is what allows this cardholder to have its semi-cylindrical spine.

Similarly, you could just use the laser engraver to cut sheets of plastic. Here, you’ve got a merry-go-round made from a prism-film acrylic sheet. The joineries come out perfect, the details are immaculate, and the laser machine allows you to create incredibly slim, intricate parts that don’t break off while you’re making them – something that’s sure to happen if you took the same thing to a jigsaw machine or a glass-cutter.

But here’s the most remarkable part of the laser machines and the F1 Ultra specifically. It works on metal (as you probably saw with the first image featuring a bedazzled iPad), but what it can also do apart from mere engraving, is create colors too. I was absolutely floored when I first saw this rendition of Starry Night on a sheet of presumably steel. While you’d think etching metal simply turns it black, you can also modulate the intensity of your laser to create different colors. If you’ve ever seen a car tailpipe with that weird rainbow finish caused by the heat of the exhaust, that’s exactly what the laser machine does too.

Controlled exposure to certain temperatures can cause the metal to change colors. Do it using a hyper-accurate laser and you can ‘print’ on metal simply by applying heat. I asked xTool’s people time and time again if this was some form of printing, just because of how impressive this turned out to be. Every color you see there is the result of a laser beam applying heat, causing the metal to turn either black, blue, cyan, rust, or even yellow.

Of course, I had to try out the machine for myself – luckily, the folks at xTool were happy to oblige. All I did was upload a photo of myself to the F1 Ultra (using a very easy QR Code-based system) and have it oriented on the object in question. xTool had an entire batch of cinnamon leaves handy, just for this exercise… in fact, Yao Ming (the Chinese basketball phenom) was on the floor that day, and he was presented with a laser-engraved leaf with his face too.

Anyway, the entire process took all of 10 minutes from start to finish, leaving me (leafing?) with an immaculately engraved portrait of myself on a leaf. Would I consider splurging $3-4k on a laser machine? The truth is, probably not – I’m very bad with money so I’ve had to work hard to exercise self-restraint – but here’s where something changed. I now know what versatility a laser machine like the F1 Ultra is capable of, and if I were to think about investing in one, I’d be much more informed in my decision, rather than going for an impulse purchase. I’m assuming I’ve done the same for you too…

The post Everything You Can Make With A Laser Engraving Machine: Hands-On with the xTool F1 Ultra first appeared on Yanko Design.

![“[You] Build a Movie Like You Build a Fire”: Lost Highway DP Peter Deming on Restorations, Lighting and Working with David Lynch](https://filmmakermagazine.com/wp-content/uploads/2025/03/1152_image_03-628x348.jpg)

![‘Yellowjackets’: Christina Ricci Talks Misty Quigley’s Evolution, That Leather Jacket, Her Complicated Walter Bond & The Show’s Shifting Arc [Interview]](https://cdn.theplaylist.net/wp-content/uploads/2025/06/12125824/Christina-Ricci-Yellowjackets.jpg)

![‘Dying For Sex’: Creators Liz Meriwether & Kim Rosenstock Talk Michelle Williams & Jenny Slate Fearlessness, Sexual Awakenings & The Intimacy Of Showing Up For Friends [Interview]](https://cdn.theplaylist.net/wp-content/uploads/2025/04/04151935/FXs-Dying-for-Sex-Media-Guide-3.jpg)

![Freakonomics Says United Pays $33 for Every Business Class Meal—Here’s Why That Number Doesn’t Work [Roundup]](https://viewfromthewing.com/wp-content/uploads/2022/06/20220619_113816-scaled.jpg?#)

.jpg?width=1920&height=1920&fit=bounds&quality=70&format=jpg&auto=webp#)

.jpg)

![[Podcast] Problem Framing: Rewire How You Think, Create, and Lead with Rory Sutherland](https://justcreative.com/wp-content/uploads/2025/06/rort-sutherland-35.png)