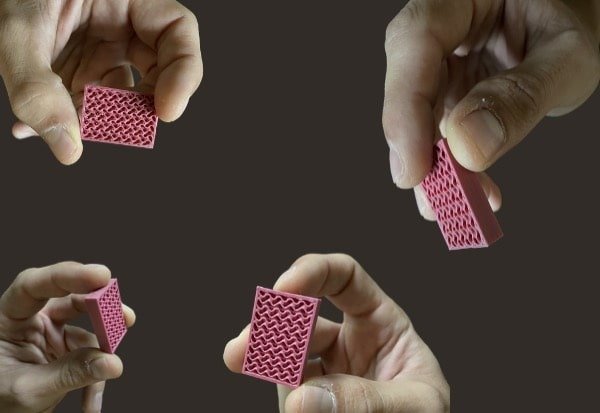

Far Cheaper, Pellet-Based Industrial 3D Printing

3D printing on an industrial scale brings two costs: The five-figure price tag of the printer, and the ongoing costs of the feedstock. For the latter, you've got FDM filaments like PLA or ABS, or liquid resin, which costs roughly twice as much as filament.Pollen AM, a French company that develops additive manufacturing solutions, aims to reduce your material costs. The company's PAM (Pellet Additive Manufacturing) line of 3D printers have been specifically designed to use injection-molding-grade pellets, rather than filaments or liquid resin, as its feedstock. Why pellets? Because injection molding is still a globally dominant manufacturing method, pellets are widely available and cheap--about 5 to 10 times cheaper than filament, and far cheaper than resin. With a PAM machine, the cost per print goes way down.Unlike some other industrial 3D printers, the PAM doesn't lock you in to a proprietary feedstock. Any pellet suitable for injection molding can be used with the machine, freeing up sourcing options. Additionally, the machine can be fitted with up to four extruders, allowing multi-material prints. The company uses a slicer (the software that slices your design into print layers) that's open-source, so you can tweak its settings to suit your chosen material. The scale of the machine is limited—more in line with product development than, say, propmaking. The build area is a 300mm (11.8") cylinder that's 300mm tall.Whether your organization can enjoy the savings of PAM depends on the specific math of your production. The machine itself starts at around $65K. A competing FDM model might run you anywhere from $15K to $100K, and a resin-based printer, $10K to $25K. Let the bean counters sort that one out.

3D printing on an industrial scale brings two costs: The five-figure price tag of the printer, and the ongoing costs of the feedstock. For the latter, you've got FDM filaments like PLA or ABS, or liquid resin, which costs roughly twice as much as filament.

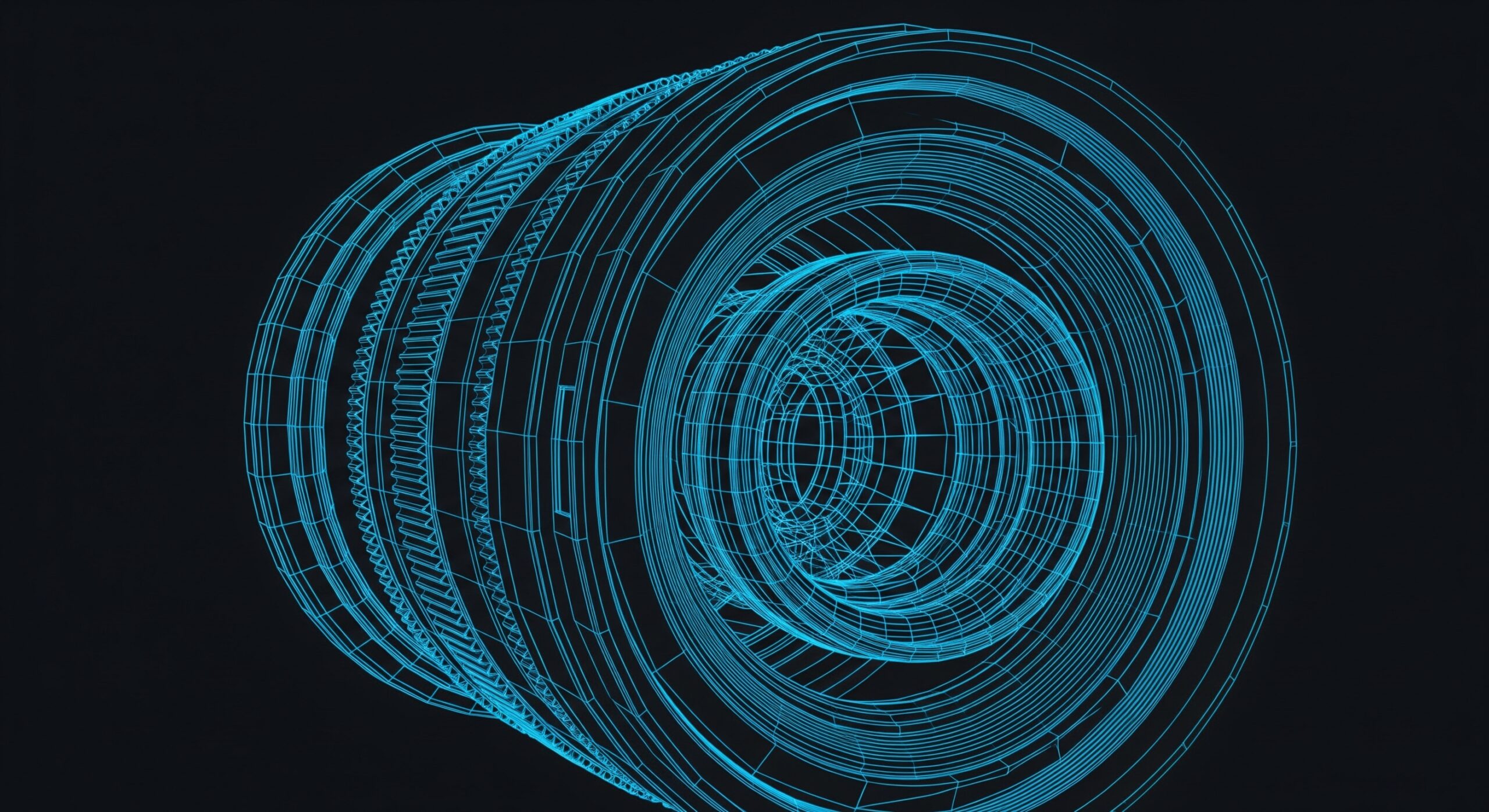

Pollen AM, a French company that develops additive manufacturing solutions, aims to reduce your material costs. The company's PAM (Pellet Additive Manufacturing) line of 3D printers have been specifically designed to use injection-molding-grade pellets, rather than filaments or liquid resin, as its feedstock.

Why pellets? Because injection molding is still a globally dominant manufacturing method, pellets are widely available and cheap--about 5 to 10 times cheaper than filament, and far cheaper than resin. With a PAM machine, the cost per print goes way down.

Unlike some other industrial 3D printers, the PAM doesn't lock you in to a proprietary feedstock. Any pellet suitable for injection molding can be used with the machine, freeing up sourcing options. Additionally, the machine can be fitted with up to four extruders, allowing multi-material prints.

The company uses a slicer (the software that slices your design into print layers) that's open-source, so you can tweak its settings to suit your chosen material.

The scale of the machine is limited—more in line with product development than, say, propmaking. The build area is a 300mm (11.8") cylinder that's 300mm tall.

Whether your organization can enjoy the savings of PAM depends on the specific math of your production. The machine itself starts at around $65K. A competing FDM model might run you anywhere from $15K to $100K, and a resin-based printer, $10K to $25K. Let the bean counters sort that one out.

![‘Predator: Killer of Killers’ Directors on the Anthology Format and Historical Accuracy [Interview]](https://i0.wp.com/bloody-disgusting.com/wp-content/uploads/2025/06/Screenshot-2025-05-19-121021-1.jpg?fit=1694%2C802&ssl=1)

![Vampiro Returns — To Build a Cult on the Airwaves [Podcast]](https://bloody-disgusting.com/wp-content/uploads/2025/06/vAMPIRO-bANNER-TEMP-1024x576.png)

![The Sweet Cheat [THE PAST REGAINED]](https://jonathanrosenbaum.net/wp-content/uploads/2011/05/timeregained-womanonstairs.png)

![United Quietly Revives Solo Flyer Surcharge—Pay More If You Travel Alone [Roundup]](https://viewfromthewing.com/wp-content/uploads/2025/04/united-737-max-9.jpg?#)